T.O. 33A1-3-358-11/TM 11-6625-842-15

Section IV

NAVAIR 16-30APM239-2

Paragraphs 4-19 to 4-23

should vary with the input pulse train up to an amplitude of + 5 0.5 volts; above this point, the limited pulse

train should remain at +5 0.5 volts.

Remove the cable, oscilloscope and the simulator test set.

d.

Place the PANEL LIGHTS switch in the 6V position or the 28V position depending on whether the

e.

control box used requires 6-volt or 28-volt lighting.

Check that all edge-lighted panel lamps are illuminated.

f.

Place the PANEL LIGHTS switch to the OFF position.

g.

Place the TEST CONDITION switch in the VOLTS position.

h.

i.

Connect the multimeter to pin m of MODE C ENCODER connector J5.

Place MODE C ENCODER SIMULATOR switch C1 in the OFF position and observe that the multim-

j.

eter indicates +20 1.5 volts dc.

Place MODE C ENCODER SIMULATOR switch C1 in the ON position and observe that the multim-

k.

eter indicates +1.5 0.5 volts dc.

l.

Disconnect the multimeter.

4-19. PREVENTIVE MAINTENANCE.

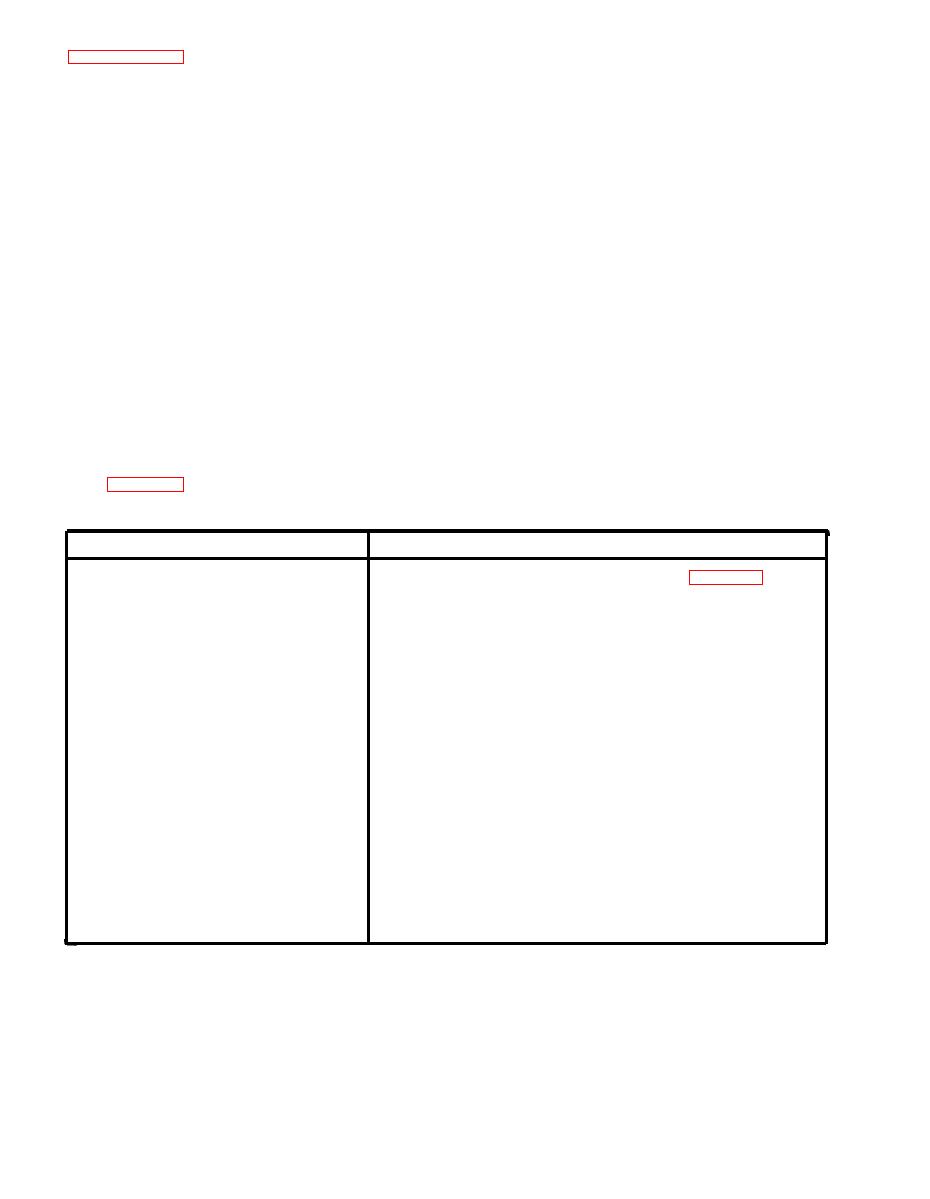

4-20. Figure 4-2 outlines the checks to be made to determine and maintain serviceability. The chart indi-

cates what to inspect and the procedure for inspection. The checks should be performed weekly when the test

set is in relatively continuous use. They should be performed monthly when the test set is used intermittently.

PROCEDURE

ITEM

Check the equipment for completeness (figure 1-3). In

particular make sure that the transit case cover and the

various accessory items have not been misplaced.

Clean the exterior of all units with a clean, lint-free

Exterior Surfaces

cloth using cleaning compound Federal Stock No. 7930-

395-9542 or equivalent to remove any accumulated oil

film and/or dust from the outside of the units. Dry all

surfaces thoroughly with a clean cloth.

Inspect painted surfaces for spots, chips, cracks or cor-

rosion. Touch up or refinish as necessary.

Check for bent or broken pins, or damaged threads.

Cables, Connectors,

Clean dirt from contacts. Check cables for cuts, kinks,

Adapters, and Extender

breaks, or fraying. Repair any cuts, kinks, breaks, or

Boards

fraying. Repair any cuts in cable insulation by covering

with rubber tape and then with friction tape. Repair or

replace all damaged cables. Replace all damaged con-

nectors, adapters, and extender boards.

Controls and Switches

Observe knobs and switches for proper mechanical

action by setting each control through each of its possi-

ble positions.

Figure 4-2. Maintenance Chart

4-21. CALIBRATION CHECKS.

4-22. This section describes the procedures for zeroing and checking the accuracy of the voltmeter and am-

meter on the test set and of the fault isolation meter.

periodically for proper zero readings. Adjusting screws are located on the face of each meter for the purpose

of making any corrections required.

4-4