TM 11-6625-828-45

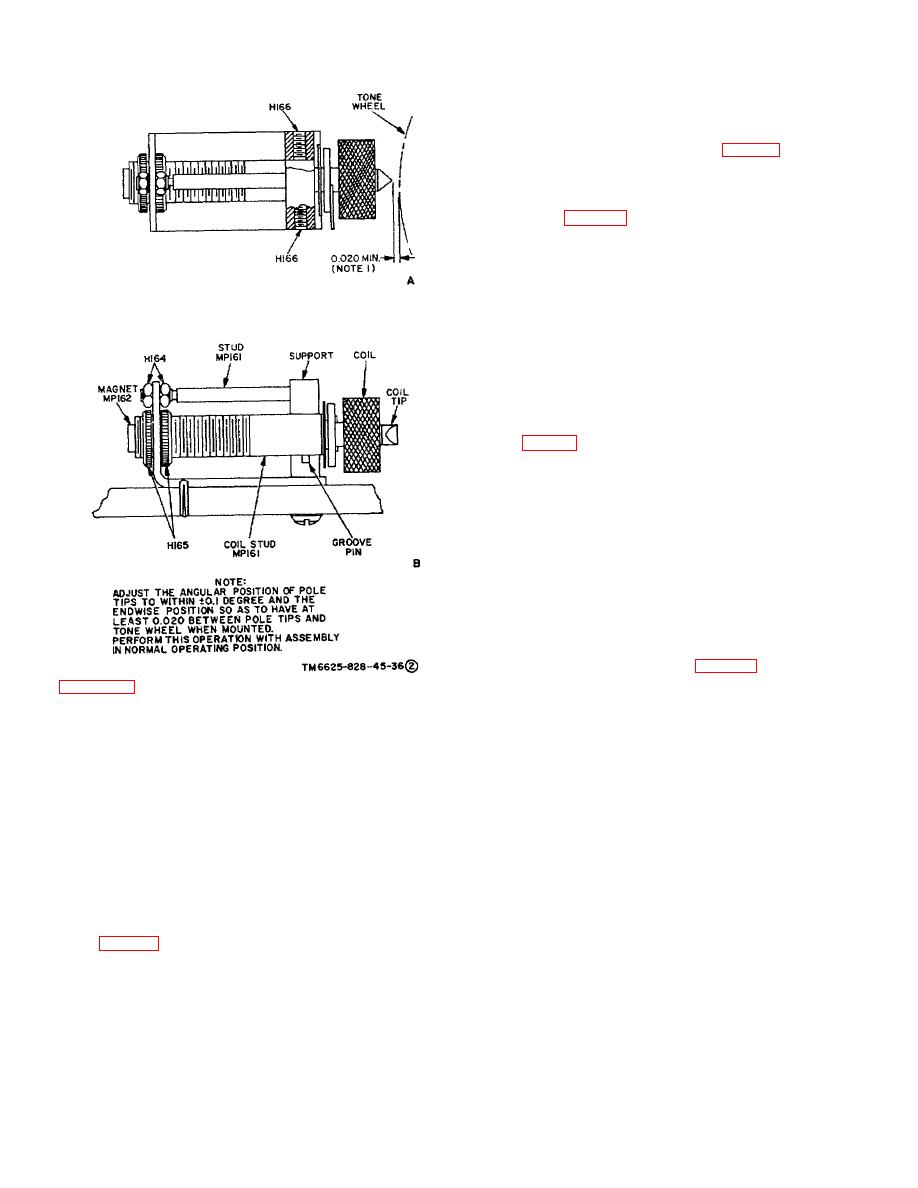

the set 3-14 on the side of the support facing the

direction in which the coil is to be moved.

(3) Connect the vacuum tube voltmeter test A,

leads to the terminals of coil L102 (fig. 3-8()) and adjust

the gap between the coil tip and the tone wheel until the

vacuum tube voltmeter indicates 14 volts -+0.01. Gap

adjustment is accomplished by backing off one knurled

nut H165 (fig. 3-8(1))and tightening the other nut.

Tighten the nut on the side of the bracket facing the

direction in which the tip is to be moved.

NOTE

The gap between the coil tip and the

tone wheel must always be greater

than 0.007 inch.

(4) Disconnect the vacuum tube voltmeter

and recheck the course error. If necessary, readjust the

angular position of coil L102 until the indicated error is

0.00.

(5) If coil L102 cannot be moved enough to

obtain a course error of 0.0 at 180 track also adjust coil

L101 (fig. 3-8()).

(6) If coil L101 was adjusted, coil L101 must

be set for a voltage of 14 volts i 0.01, and variable

resistor R138 (fig. 22) must be readjusted for a 0.00

course error (b(4) above).

d. 30 Track Alignment. Set the test set OMNI

TRACK switch to 30 and check the angular position and

voltage output of coil L104 (fig. 3-80) in the same

manner as specified for coil L102. Coil L104 voltage

must be 14 volts +0.01 and the course error, if any,

must be corrected to 0.0.

e. 1200 Track Alignment. Set the test set OMNI

TRACK switch to 120 and check the angular position and

voltage output of coil L105 (fig. 3-8()) in the same

manner as specified for coil L102. Coil L105 voltage

must be 14 volts _+0.01 and the course error, if any,

wheel generator.

must be corrected to 0.0.

(3) Remove the decade resistance box

f. 15 Track Alignment. Allow the test set to warm

replace with a fixed resistor (R139) having same

up for a minimum period of 2 hours, and then proceed as

approximate value as noted in (2) above

follows:

(4) Adjust variable resistor R138 until course

(1) Set the test set OMNI TRACK switch to

checker again indicates 0.00.

the 0 and set the course checker SELECTOR switch to

c. 180 Track Alignment. Set the test OMNI

0.

TRACK switch to 180 and proceed follows:

(2) Note the course error, if any, indicated on

(1) Set the course checker COURSE s, to

the course checker DIkGREES meter. Adjust variable

1800 and read the course error, if any, on course

resistor R188 (b(4) above), as necessary, to obtain a

checker DEGREES meter.

0.00 error.

(2) Adjust the angular position of coil 102 (fig.

(3) Set the test set OMNI TRACK switch to 15

3-80) until the course has 0.00 el Angular position

and the course checker SEL4ECTOR switch to 15.

adjustment is accomplished backing off one setscrew

H166 (fig. 3-8) tightening the other setscrew. Loosen

3-14