TM 11-6625-820-45

b. Tools. All tools required are contained

ASM-110.

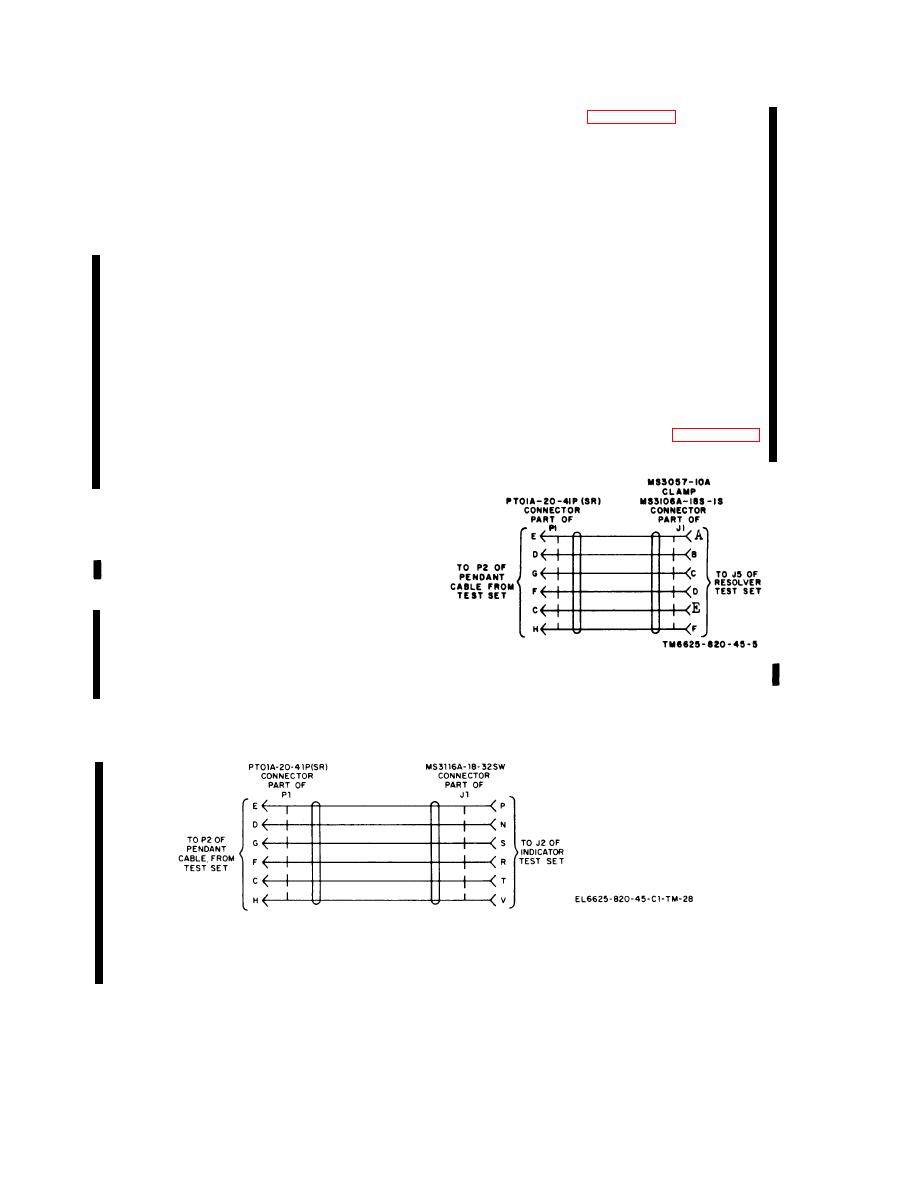

Refer to figures 4-1, 4-1.1, and

4-1.2 and construct the cables as described

in Tool Kit, Electronic Equipment TK105/G,

below.

Federal Stock No. 5180-610-8177.

a . Resolver Test Set and Indicator Test

c. Materials.

Set Cables.

(1) 1/4-inch barrel diameter.

(1) S o l d e r six 2-foot lengths of # 22

(2) T e l e p h o n e plug (1/4-inch diameter

A W G stranded, i n s u l a t e d wire to

barrel).

pins C, D, E, F, G, and H of each

(3) Wire, copper, i n s u l a t e d , stranded #

male connector P1.

22 AWG (40 feet long).

(2) Label the loose ends of the six wires

(4) Connectors ( 3 ) , Bendix PTOlA-20-

with the pin number to which each

40P(SR).

wire is connected.

PTO1A-12-10P

(5) Connector,

Bendix

(3) Slip a 2-inch length of spaghetti over

(SR).

the loose ends of the six wires.

(6) Clamp MS3057-10A.

(4) Place clamp MS3057-10A over the

(7) Connector MS3106A-18S-1S.

end of the spaghetti on the resolver

(8) Connector MS3116A-18-32SW.

test set cable.

(9) B i n d i n g posts (7) Superior Electric

(5) C o n n e c t the loose ends of the six

Company DF 30RC.

w i r e s to the pins of the J1 female

(10) Spaghetti, 3 / 4 - i n c h diameter (5.5

connectors as shown in figures 4-1

feet long).

and 4-1.1.

(11) Small enclosed metal box 3 x 4 x 5

inches.

4-3. Test Facilities

Primary power requirements are 27.5 volts

dc at 33 watts and 115 volts, 400 cps at 92

watts. Temperature, humidity, and atmos-

pheric pressure are not critical.

4-4. Fabricated Cable Construction

Details

Fabricated cables are required to connect

the test set to Test Set, Resolver AN/ASM-

Figure 4-1. Fabricated cable to resolver test set,

1 0 1 and Test Set, Indicator, Course AN/

construction details.

Figure 4-1.1. Fabricated cable to indicator test set, construction details.

4-2 Change 2